2C multi-purpose anchor SHARK® TWIST One anchor. Eight knots.

2C plastic multi-purpose anchor Shark TWIST

DWL-PLA-SHARK-TWIST-10X56

Register now and access more than 125,000 products

One anchor. Eight knots.

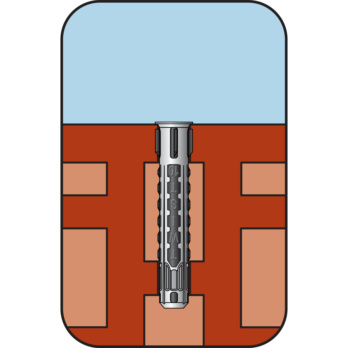

- The anchor can be inserted flush using just one finger, without the need for a hammer

- Easy to screw in, which allows for quick fastening

For universal use

- For fastening components in conjunction with a screw with a wood thread and metric thread

- Each anchor size can be combined with several screw diameters

High level of safety

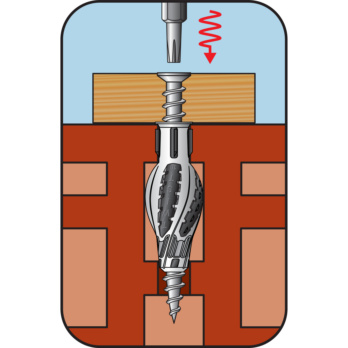

- Eight knots with extremely large contact surface provides secure hold

- High load values for anchors in a redundant non-structural system in concrete and masonry in conjunction with the ASSY-D screw, proven in ETA assessment, for greater safety

- Low installation torque and high overtorque

- Overwind protection, prevents overtightening of the anchor in the drill hole

Durability and resistance

- Resistant to rotting, weathering and ageing

- UV-resistant for up to six weeks

Wide range of fastening options

- Ideal for fastening light to medium loads

- Can be used outdoors or in wet rooms in conjunction with a stainless steel screw

Other advantage

- Due to the special plastic combination of the SHARK TWIST, even screws with metric threads can be screwed in without any problems, for example, threaded studs or rods for suspended items in plumbing installations or metric screws

ETA-22/0877

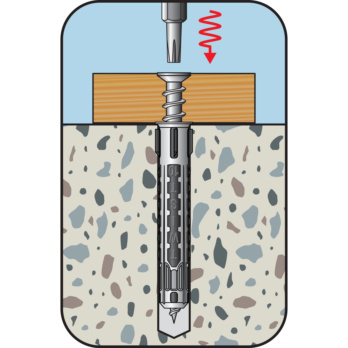

For installation, we recommend the ASSY-D screw.

Autoclaved aerated (cellular) concrete

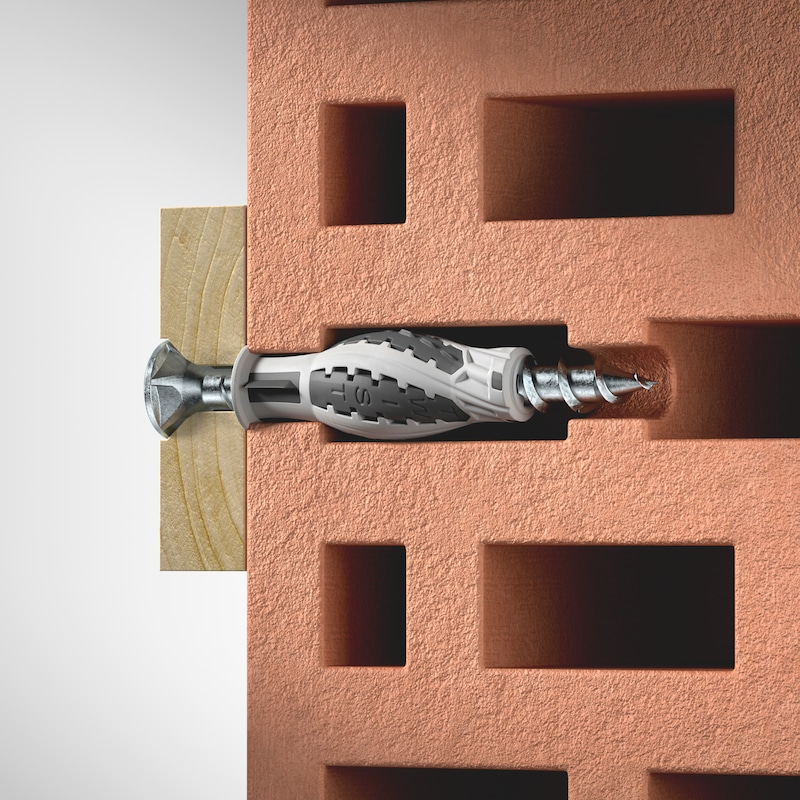

Vertically perforated brick with small bars

Vertically perforated bricks with lateral bars

Concrete

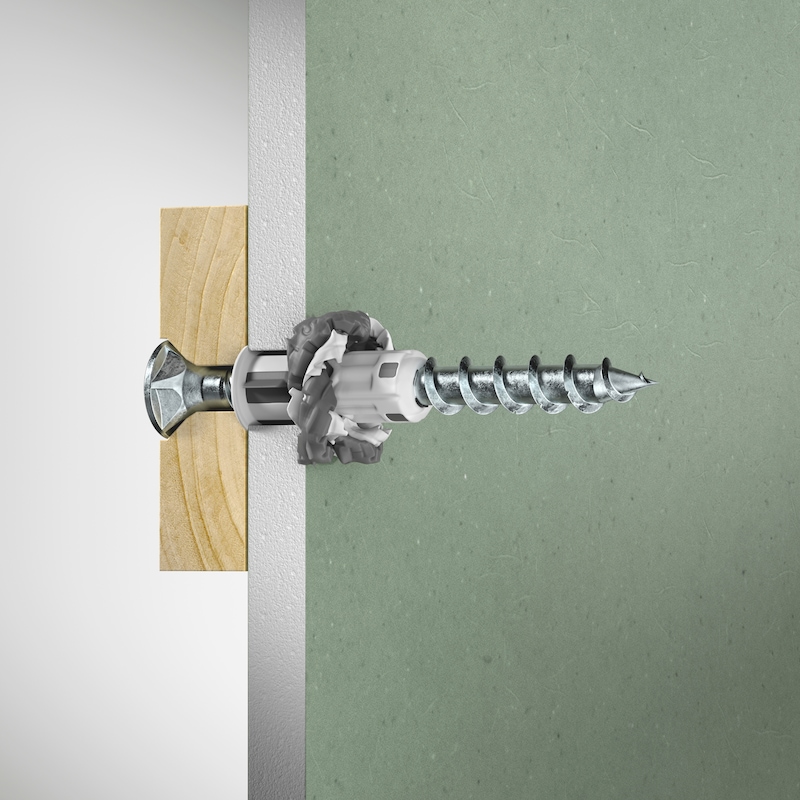

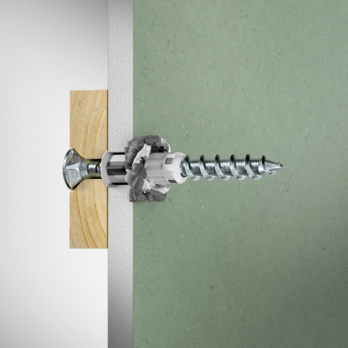

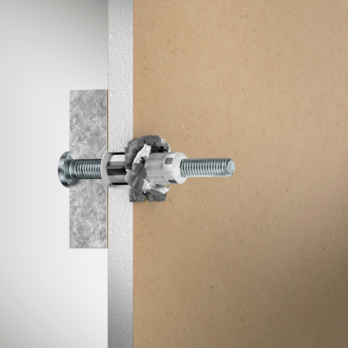

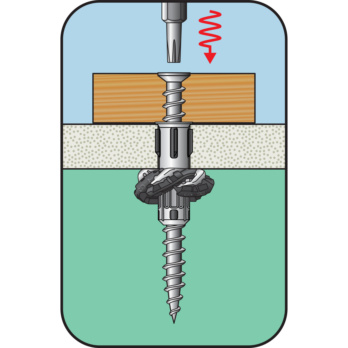

Panel materials with chipboard screw

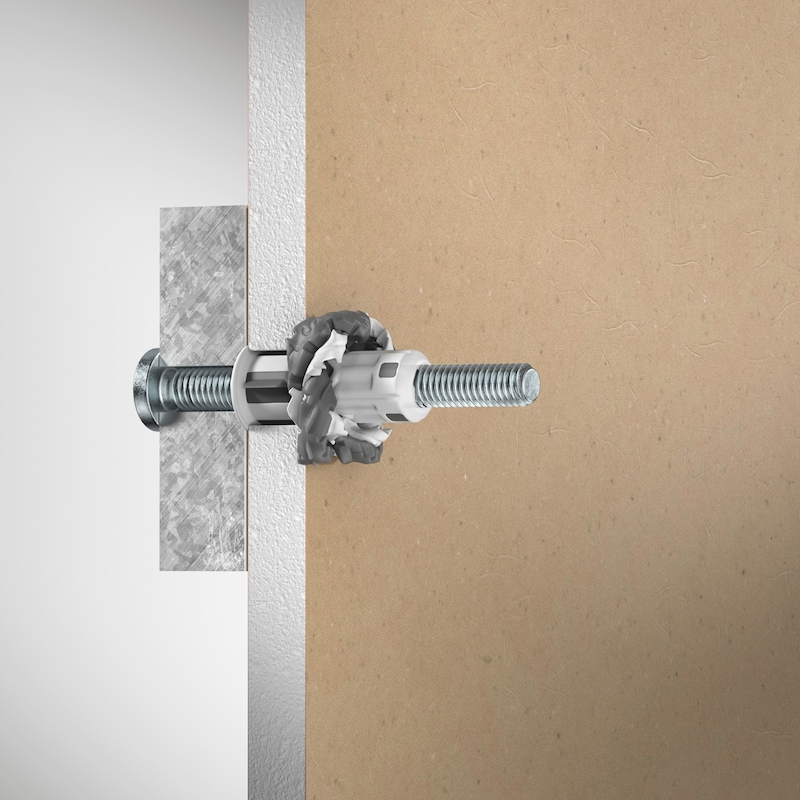

Panel materials with metric screw

Inserting the anchor

Can be used with one finger without a hammer

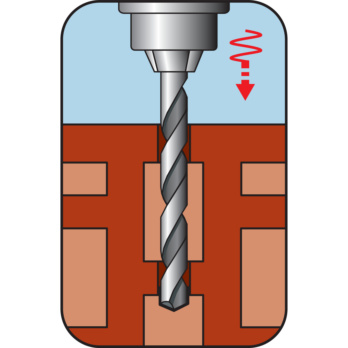

Drill the hole

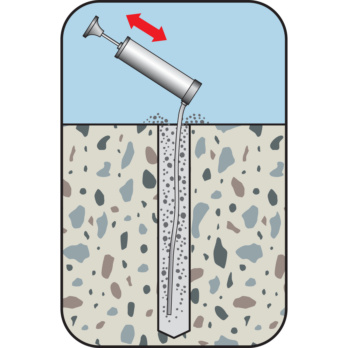

Remove drill cuttings from drill hole

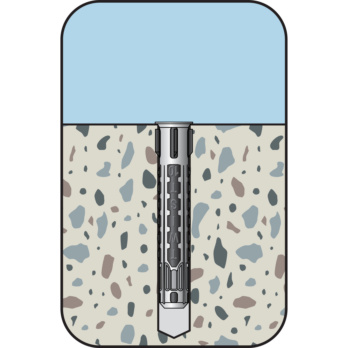

Place anchors in drill hole

Screw in the screw flush through the attachment part

Drill the hole

Place anchors in drill hole

Screw in the screw flush through the attachment part

Drill the hole

Place anchors in drill hole

Screw in the screw flush through the attachment part

ETA-22/0877

Datasheets(X)

- Universal plastic anchor

- Can be used in concrete, solid brick, solid sand-lime block, vertically perforated brick, hollow sand-lime block, autoclaved aerated concrete, gypsum plasterboard, gypsum fibreboard

- Suitable for fastening light to medium loads, such as curtain rails, wall shelves, lightweight hanging cabinets, picture frames, mirrors, lamps, cable ducts, cable clamps, electrical switches, washbasins, towel rails, information signs and motion detectors

Anchor diameter | 10 mm |

Material | Polypropylene - PP / polyamide - PA |

Colour | White, Anthracite |

Anchor length (l) | 56 mm |

Nominal drill-bit diameter (d 0) | 10 mm |

Drill hole depth (t) | 65 mm |

Edge clearance (a r) | 80 mm |

Embedding depth (h s) | 55 mm |

Min./max. required screw diameter | 6-8 mm |

Min./max. temperature conditions | -40 to 50 °C |

| Stone type | Mirror thickness dU [mm] | Minimum compressive strength [N/mm2] | Fadm [kN] 1)5) (for individual anchors or an anchor group) | ||||

| SHARK TWIST 6 | SHARK TWIST 8 | SHARK TWIST 10 | SHARK TWIST 12 | SHARK TWIST 14 | |||

| Effective anchorage depth | hnom [mm] | 35 | 45 | 55 | 65 | 75 | |

| Hollow-core prestressed concrete EN 206:2013+A1:2016 | ≥25 | ≥ C30/37 | 0,30 | 0,48 | 0,48 | 0,48 | 0,48 |

| ≥40 | ≥ C30/37 | 0,60 | 0,60 | 0,60 | 0,60 | 0,60 | |

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of F = 1.4 have been taken into account. For the combination of tensile and shear loads, please note EAD 330284-00-0604 2) Maximum long-term temperature 3) Maximum short-term temperature 4) For other types of stone, raw densities, minimum compressive strengths or temperature ranges, please refer to the assessment ETA-22/0877 5) The stone geometry should be compared with the assessment ETA-22/0877. | |||||||

| SHARK TWIST load capacities | |||||

| Anchor size | 6 | 8 | 10 | 12 | 14 |

| Base material | Frec [kN] | Frec [kN] | Frec [kN] | Frec [kN] | Frec [kN] |

| Concrete ≥ C20/25 | 0,9 | 1,2 | 2 | 3 | 3,2 |

| Solid brick ≥ MZ12 | 0,6 | 0,9 | 1,5 | 2 | 2,2 |

| Solid calcium silicate block ≥ KSV12 | 0,7 | 1,4 | 2,3 | 3 | 3,2 |

| Vertically perforated brick ≥ Hlz12 | 0,25 | 0,35 | 0,4 | 0,5 | 0,6 |

| Hollow calcium silicate block ≥ KSL12 | 0,5 | 0,7 | 1 | 1,4 | 1,6 |

| Autoclaved aerated concrete PB2; PP2 | 0,15 | 0,2 | 0,25 | 0,4 | 0,5 |

| Gypsum building panels ρ ≥ 0.85 kg/dm³ | 0,22 | 0,35 | 0,5 | 0,6 | 0,7 |

| Gypsum plasterboard dia. = 12.5 mm | 0,1 | 0,2 | 0,2 | - | - |

| Gypsum plasterboard dia. = 25 mm | 0,2 | 0,25 | 0,35 | - | - |

| Gypsum fibreboard dia. = 10 mm | 0,3 | 0,35 | 0,45 | - | - |

| Assignment of metric fasteners by anchor size | |||||

| Anchor dia. 6 | Anchor dia. 8 | Anchor dia. 10 | Anchor dia. 12 | Anchor dia. 14 | |

| Suitable screw diameter (wood thread) | 4 to 5 mm | 5 to 6 mm | 6 to 8 mm | 8 to 10 mm | 10 to 12 mm |

| Suitable screw diameters (metric) - solid and perforated construction materials | M4 | M5 | M6 | M8 | M10 |

| Suitable screw diameters (metric) - panel materials | M3 | M4 | M5 | - | - |

| Installation parameters: Concrete + masonry | ||||||

| Anchor diameter [mm] | SHARK TWIST 6 | SHARK TWIST 8 | SHARK TWIST 10 | SHARK TWIST 12 | SHARK TWIST 14 | |

| Nominal drill dia. | d0 [mm] | 6 | 8 | 10 | 12 | 14 |

| Dia. of cutting edges | dcut ≤ [mm] | 6,4 | 8,45 | 10,45 | 12,5 | 14,5 |

| Drill hole depth | h1 ≥ [mm] | ls + 5 mm - tfix | ||||

| Embedment depth of the anchor sleeve | hnom [mm] | 35 | 45 | 55 | 65 | 75 |

| Through hole in the fixture | df ≤ [mm] | 5,5 | 6,5 | 8,5 | 10,5 | 12,5 |

| Performance data: Masonry4), (temperature range 30 °C2)/50 °C3)) | ||||||

| For other types of stone, raw densities, minimum compressive strengths, edge distances, spacings or temperature ranges, please refer to the assessment ETA-22/0877 | ||||||

| Stone type | Stone format [mm] | Raw density class [kg/dm3] | Minimum compressive strength [N/mm2] | Fadm [kN] 1)5) (for individual anchors or an anchor group) | ||

| SHARK TWIST 10 | SHARK TWIST 12 | SHARK TWIST 14 | ||||

| Effective anchorage depth | hnom [mm] | 55 | 65 | 75 | ||

| Masonry brick Mz, EN 771-1:2011+A1:2015 | ≥NF (≥240x115x71) | ≥ 1.8 | 10 | 0,34 | 0,42 | 0,42 |

| 12,5 | 0,42 | 0,57 | 0,57 | |||

| 15 | 0,57 | 0,71 | 0,71 | |||

| 20 | 0,71 | 1,00 | 1,00 | |||

| 25 | 0,85 | 1,28 | 1,28 | |||

| 35 | 1,28 | 1,57 | 1,57 | |||

| 45 | 1,71 | 1,85 | 2,00 | |||

| 54,8 | 1,85 | 2,00 | 2,14 | |||

| Vertically perforated brick HLz, EN 771-1:2011+A1:2015 | ≥2DF (≥240x115x113) | ≥1.2 | 10 | 0,21 | 0,42 | 0,57 |

| 12,5 | 0,25 | 0,57 | 0,71 | |||

| 15 | 0,34 | 0,57 | 0,71 | |||

| 20 | 0,42 | 0,71 | 0,71 | |||

| 24,1 | 0,57 | 0,71 | 0,71 | |||

| Solid calcium silicate block KS, EN 771-2:2011+A1:2015 | ≥NF (≥240x115x71) | ≥ 1.8 | 10 | 0,34 | 0,42 | 0,42 |

| 12,5 | 0,42 | 0,57 | 0,57 | |||

| 15 | 0,57 | 0,71 | 0,71 | |||

| 20 | 0,71 | 1,00 | 0,85 | |||

| 25 | 1,00 | 1,28 | 1,14 | |||

| 35 | 1,42 | 1,57 | 1,57 | |||

| 45 | 1,71 | 1,85 | 2,00 | |||

| 49,4 | 1,71 | 1,85 | 2,00 | |||

| Solid calcium silicate block KS, EN 771-2:2011+A1:2015 | ≥4DF (≥248x175x248) | ≥ 1.8 | 10 | 0,85 | 1,00 | 1,00 |

| 12,5 | 1,00 | 1,14 | 1,14 | |||

| 15 | 1,14 | 1,14 | 1,28 | |||

| 20 | 1,28 | 1,42 | 1,42 | |||

| 23,4 | 1,28 | 1,42 | 1,42 | |||

| Hollow calcium silicate block KS L, EN 771-2:2011+A1:2015 | ≥2DF (≥240x115x113) | ≥ 1.8 | 10 | 0,42 | 0,71 | 0,71 |

| 12,5 | 0,57 | 0,71 | 0,71 | |||

| 15 | 0,57 | 0,71 | 0,71 | |||

| 18,8 | 0,71 | 0,71 | 0,71 | |||

| Hollow calcium silicate block KS L, EN 771-2:2011+A1:2015 | ≥8DF (≥248x240x238) | ≥ 1.8 | 7,5 | - | 0,57 | 0,71 |

| 10 | - | 0,71 | 0,71 | |||

| Solid blocks made of lightweight concrete V and Vbl, EN 771-3:2011+A1:2015 | ≥NF (≥240x115x71) | ≥1.2 | 2,5 | 0,21 | 0,34 | 0,42 |

| 5 | 0,42 | 0,57 | 0,57 | |||

| 7,3 | 0,57 | 0,71 | 0,71 | |||

| Solid blocks made of lightweight concrete V and Vbl, EN 771-3:2011+A1:2015 | ≥NF (≥240x115x71) | ≥2.0 | 12,5 | 0,85 | 1,14 | - |

| 15 | 1,00 | 1,42 | - | |||

| 20 | 1,28 | 1,85 | - | |||

| 25 | 1,71 | 2,00 | - | |||

| 29 | 1,85 | 2,00 | - | |||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of F = 1.4 have been taken into account. For the combination of tensile and shear loads, please note EAD 330284-00-0604 2) Maximum long-term temperature 3) Maximum short-term temperature 4) For other types of stone, raw densities, minimum compressive strengths or temperature ranges, please refer to the >>assessment ETA-22/0877 5) The stone geometry should be compared with the assessment ETA-22/0877. | ||||||

| Performance data: Concrete Anchors in a redundant non-structural system | |||||||

| Anchor diameter | [mm] | SHARK TWIST 6 | SHARK TWIST 8 | SHARK TWIST 10 | SHARK TWIST 12 | SHARK TWIST 14 | |

| Embedment depth of the anchor sleeve | hnom [mm] | 35 | 45 | 55 | 65 | 75 | |

| Centric tension load1) for individual anchors or an anchor group | Concrete = C12/15 Nadm [kN] | 30 °C2)/50 °C3) | 0,48 | 0,8 | 1,6 | 2,2 | 2,4 |

| Concrete ≥ C16/20 Nadm [kN] | 30 °C2)/50 °C3) | 0,6 | 1,2 | 2,2 | 2,8 | 3,2 | |

| Shear load1) for individual anchors or an anchor group | Vadm | [kN] | 1,62 | 2,59 | 4,67 | 6,79 | 8,55 |

| Minimum member thickness | hmin | [mm] | 100 | 100 | 100 | 120 | 120 |

| Characteristic edge distance | ccr [mm] | C12/15 | 110 | 110 | 110 | 140 | 140 |

| ≥ C16/20 | 80 | 80 | 80 | 100 | 100 | ||

| Characteristic spacing | scr [mm] | C12/15 | 110 | 110 | 130 | 140 | 155 |

| ≥ C16/20 | 80 | 80 | 90 | 100 | 110 | ||

| Minimum edge distance4) | cmin [mm] | C12/15 | 110 | 110 | 110 | 140 | 140 |

| ≥ C16/20 | 80 | 80 | 80 | 100 | 100 | ||

| Minimum spacing4) | smin [mm] | C12/15 | 110 | 110 | 110 | 140 | 140 |

| ≥ C16/20 | 80 | 80 | 80 | 100 | 100 | ||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of F = 1.4 have been taken into account. For the combination of tensile and shear loads, please note EAD 330284-00-0604 2) Maximum long-term temperature 3) Maximum short-term temperature 4) Admissible load must be reduced | |||||||